The Critical Role of Guardrails in Highway Safety: Enhancing Protection on Modern Roadways

In the fast-paced world of modern transportation, highways serve as the vital arteries connecting cities, regions, and even countries. As millions of vehicles traverse these road networks daily, ensuring the safety of motorists, passengers, and even pedestrians has become an utmost priority. Among the many engineering marvels designed to enhance highway safety, guardrails stand out as an unassuming yet indispensable component. These seemingly simple structures play a pivotal role in reducing the severity of accidents, preventing vehicles from veering off road, and minimizing potential hazards along high-speed roadways. This article explores the multifaceted functions of guardrails, their evolution over time, different types available, and the best practices for their installation and maintenance, highlighting their crucial role in creating safer highway environments.

The Fundamental Purpose of Guardrails

At their core, guardrails are designed to act as a protective barrier between vehicles and potential hazards along the roadside. These hazards can include steep embankments, sharp curves, bodies of water, utility poles, bridge abutments, or even oncoming traffic in the case of median barriers. The primary goal is to redirect out-of-control vehicles back onto the roadway while minimizing the risk of rollovers, head-on collisions, or collisions with fixed objects. By absorbing and distributing the impact energy, guardrails help reduce the forces exerted on the vehicle and its occupants, significantly improving the chances of survival in the event of an accident.

Statistics from various transportation authorities around the world underscore the effectiveness of guardrails in enhancing road safety. For example, the Federal Highway Administration (FHWA) in the United States has reported that properly installed and maintained guardrails can reduce the severity of accidents by up to 50% in certain scenarios. In areas with high-risk roadside features, this translates to fewer fatalities and serious injuries, making guardrails a cost-effective investment in highway safety infrastructure.

The Evolution of Guardrail Technology

Guardrails have come a long way since their early beginnings. The first primitive versions of roadside barriers can be traced back to simple wooden or stone fences designed to prevent horse-drawn carriages from straying off paths. As motorized vehicles became more prevalent in the early 20th century, the need for more robust and standardized guardrail systems emerged. The 1930s saw the introduction of the first steel beam guardrails, which quickly became the standard due to their durability and ability to deform upon impact, absorbing energy effectively.

Over the decades, advancements in materials science and engineering have led to the development of more sophisticated guardrail designs. Today, modern guardrails are subjected to rigorous testing protocols to ensure they meet specific safety standards, such as those set by the American Association of State Highway and Transportation Officials (AASHTO) or the European Committee for Standardization (CEN). These tests evaluate factors such as impact resistance, deflection limits, and the ability to safely redirect vehicles of different weights and speeds.

One significant evolution has been the introduction of modular and energy-absorbing components. For instance, guardrails now often feature breakaway posts or telescoping sections that reduce the risk of the guardrail itself becoming a hazard during a collision. Additionally, innovations in corrosion resistance, such as hot-dip galvanized steel or composite materials, have extended the lifespan of guardrails, making them more sustainable and cost-effective in the long run.

Types of Guardrails and Their Applications

Not all guardrails are created equal, and their design and construction vary depending on the specific roadside conditions and safety requirements of a particular highway segment. Here are some of the most common types of guardrails and their typical applications:

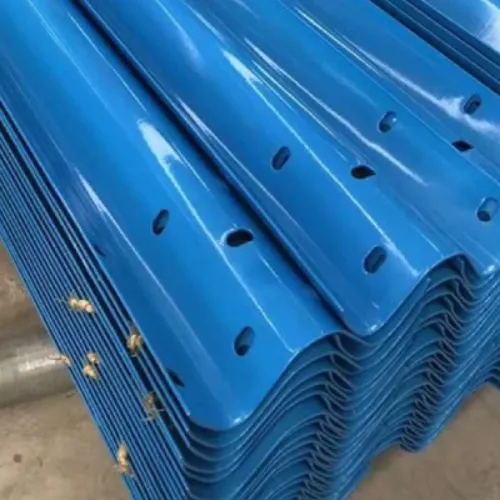

1. Steel Beam Guardrails

Perhaps the most widely used type, steel beam guardrails consist of horizontal steel rails supported by vertical posts anchored into the ground. They are highly versatile, suitable for a variety of roadside environments, from gentle slopes to moderate hazard areas. The classic W-beam guardrail, with its distinctive corrugated profile, is a common sight on highways worldwide. Its design allows it to flex and deform upon impact, absorbing energy and redirecting the vehicle back onto the road. Steel beam guardrails are relatively easy to install and maintain, and their components can be readily replaced in case of damage.

2. Concrete Barriers

Concrete barriers, often seen in medians or high-risk areas such as bridge approaches, are heavy-duty structures designed to withstand high-speed impacts. They come in various forms, including the F-shape barrier, which is popular for its ability to efficiently redirect vehicles while minimizing vehicle damage. Concrete barriers are particularly effective in separating opposing traffic flows, preventing crossover collisions that can be extremely dangerous. While they are more expensive to install and less flexible than steel beam guardrails, their durability and high impact resistance make them ideal for high-traffic corridors and areas with a history of severe accidents.

3. Composite and Timber Guardrails

In recent years, composite materials such as fiberglass-reinforced polymer (FRP) have gained popularity for guardrail construction, especially in areas where corrosion resistance is a major concern, such as coastal highways or regions with heavy de-icing salt usage. Composite guardrails offer excellent durability, lightweight installation, and reduced maintenance requirements. Timber guardrails, on the other hand, are often used in scenic or rural areas where a more natural aesthetic is desired. While they provide some level of impact protection, their use is typically limited to low-speed roads or areas with less severe hazard potential due to their lower strength compared to steel or concrete.

4. Median Barriers

Median guardrails serve the critical function of separating traffic moving in opposite directions, preventing head-on collisions which are among the most deadly types of accidents. These can be either steel beam systems with central terminals designed to safely accommodate impacts or concrete barriers for higher protection levels. In some cases, cable median barriers, consisting of multiple steel cables tensioned between posts, are used. Cable barriers have the advantage of providing a more forgiving impact, allowing vehicles to be redirected with less damage, while still effectively preventing crossover.

Best Practices for Guardrail Installation and Maintenance

The effectiveness of guardrails hinges on proper installation and regular maintenance. Even the most advanced guardrail system will fail to perform as intended if not installed correctly or neglected over time. Here are some key considerations for ensuring optimal guardrail performance:

1. Site-Specific Design

Before installing guardrails, a thorough roadside hazard assessment should be conducted to determine the appropriate type, height, and strength of the barrier. Factors such as road geometry (curves, gradients), traffic speed, expected vehicle types, and the nature of adjacent hazards (drop-offs, obstacles) must all be taken into account. Computer-aided simulation tools are often used to model potential impacts and ensure the guardrail design meets the required safety standards for the specific location.

2. Quality Installation

Installation by trained professionals is essential to ensure that guardrails are securely anchored and aligned correctly. For steel beam guardrails, proper spacing between posts, correct burial depth, and tight fastening of the rails are critical. Concrete barriers require precise placement to ensure continuity and proper jointing to prevent cracking. Any deviations from the design specifications during installation can compromise the guardrail's ability to perform in a collision.

3. Regular Inspections and Maintenance

Guardrails are exposed to harsh environmental conditions, including weather, traffic wear and tear, and occasional minor collisions. Regular inspections should be carried out to check for signs of damage, such as bent rails, loose posts, or corrosion. Damaged components should be repaired or replaced promptly to maintain the guardrail's integrity. In the case of concrete barriers, cracks or spalling should be addressed to prevent water infiltration and structural degradation. Additionally, vegetation near guardrails should be managed to ensure clear visibility and unobstructed access for maintenance activities.

4. Upgrading Older Systems

Many highways still have older guardrail systems that may not meet current safety standards. Retrofitting these systems with modern components, such as energy-absorbing terminals or improved post designs, can significantly enhance their performance without the need for complete replacement. Authorities should prioritize upgrading guardrails in high-risk areas, using funding from safety improvement programs to ensure that infrastructure keeps pace with evolving vehicle technologies and traffic demands.

Case Study: The Impact of Guardrails on Highway Safety in Europe

To illustrate the real-world benefits of guardrails, let's look at a case study from Europe, where extensive highway networks and strict safety regulations have led to significant advancements in guardrail technology. In countries like Germany and the Netherlands, the systematic installation of modern guardrail systems along high-speed Autobahns and motorways has contributed to a steady decline in road fatalities over the past few decades.

A notable example is the use of concrete median barriers on heavily trafficked sections of the Autobahn. These barriers have been proven to effectively prevent head-on collisions, which were once a major cause of severe accidents. Additionally, the adoption of cable barriers in rural areas with gentle terrain has provided a cost-effective solution that combines safety with minimal visual impact, blending into the natural landscape while still offering reliable protection.

European countries also place a strong emphasis on guardrail maintenance, with dedicated road maintenance crews conducting regular inspections and upgrades. This proactive approach has not only improved safety but also extended the lifespan of guardrail infrastructure, making it a worthwhile investment in public safety.

The Future of Guardrails: Innovations and Sustainability

As technology continues to advance, the future of guardrails holds exciting possibilities for further enhancing safety and sustainability. One area of innovation is the integration of smart technology into guardrails, such as sensors that can detect damage or structural stress in real-time, allowing for more targeted maintenance and reducing the risk of undetected failures. These sensors could also be used to monitor traffic conditions, providing valuable data for traffic management systems.

Sustainability is another key focus, with a growing emphasis on using recycled materials and energy-efficient manufacturing processes for guardrail production. For example, recycled steel and concrete aggregates are increasingly being used, reducing the environmental impact of guardrail construction. Composite materials, which have a lower carbon footprint compared to traditional steel and concrete, are also expected to play a larger role in future guardrail designs, especially in regions with strict environmental regulations.

Moreover, as autonomous vehicles become more prevalent, guardrails may need to be designed to work in conjunction with advanced driver assistance systems (ADAS), ensuring compatibility with vehicle sensors and navigation systems. This could involve new standards for guardrail visibility, such as reflective coatings or integrated lighting, to enhance detection by autonomous vehicle cameras and radar systems.

Conclusion

In conclusion, guardrails are a cornerstone of highway safety, providing essential protection against a wide range of roadside hazards. From their humble beginnings as simple barriers to today's sophisticated, engineered systems, they have evolved to meet the ever-changing demands of modern transportation. By understanding the different types of guardrails, their applications, and the best practices for installation and maintenance, highway authorities can make informed decisions to create safer road environments for all users.

As we look to the future, the combination of technological innovation, sustainability efforts, and a continued focus on safety research will undoubtedly lead to even more effective guardrail solutions. Whether it's a steel beam guardrail gently redirecting a skidding car or a concrete barrier preventing a catastrophic head-on collision, these unassuming structures remain a testament to human ingenuity in the pursuit of safer travel. As long as highways remain a vital part of our infrastructure, guardrails will continue to play their critical role in safeguarding lives and ensuring that every journey is a safe one.

By prioritizing investment in guardrail infrastructure and adopting a proactive approach to safety, we can move closer to the goal of zero fatalities on our roadways, making guardrails not just a component of highway design, but a symbol of our commitment to protecting those who travel upon them.